Zida Zapamwamba Ndi Njira Yowongolera Ubwino

Ma valve onse amachitidwa ndi machitidwe abwino olamulira, zida zoyendera zodalirika ndi ogwira ntchito ophunzitsidwa bwino a QC, ARAN amasunga khalidwe ngati lofunika kwambiri kwa makasitomala athu.

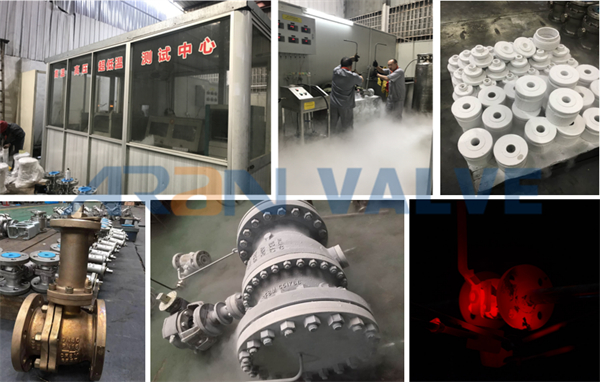

ARAN ili ndi dipatimenti yake yoyesa m'nyumba komanso labu yovomerezeka ndi gulu lachitatu kuti athe kuwongolera mwapadera, kuwunika ndi kuyesa konse kumachitika ndi oyenerera komanso odziwa zambiri.

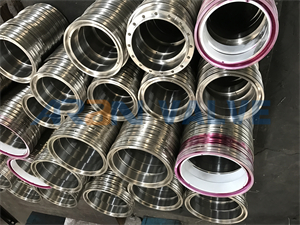

Malo opangira zida zowongolera zinthu m'nyumba, omwe amayesa kuyesa, kuyesa kuuma, kuyesa kwamphamvu, kapangidwe ka mankhwala ndi labu yamakina.

Polamula aQuality Control Plan (QCP) ndi Kuyendera ndiKuyenderaMapulani Oyesera (ITP) atha kuperekedwa kuti avomereze kasitomala isanapangidwe.

1. Vavu yaiwisi kulamulira: zowoneka ndi dimension anayendera, PMI, khoma makulidwe, Impact mayeso ngati mwa pempho, NDE ngati PT, UT, MT, RT.

2. Valve chigawo ndondomeko makina kuyendera: dimension cheke, machined pamwamba ndi mbali zinthu cheke, pempho lapadera ngati NDE mayeso ndi pempho dongosolo.

3. Kukonzekera kwa ma valve ndi kuyang'anira ntchito: Chigawo chilichonse cha valve chili pansi pa hydraulic ndi mpweya kuyesa kuyang'anitsitsa ntchito molingana ndi pempho lovomerezeka, pempho lapadera monga kuyesa kwa PAT mwa pempho la dongosolo.

4. Valve Paint, phukusi ndi kutumiza.Pempho lapadera ngati kuyendera gulu lachitatu ndi pempho la dongosolo.

General Quality Contor Process

Vavu zopangira zopangira: Kuyang'ana kowoneka ndi mawonekedwe, cheke chakuthupi, PMI, makulidwe a khoma, mayeso a Impact ngati mwa pempho, NDE.

Kuwunika kwa makina amakina a vavu: cheke cha kukula, mawonekedwe opangidwa ndi makina ndi magawo azinthu, pempho lapadera ngati mayeso a NDE popempha.

Kukonzekera kwa ma valve ndi kuyang'anira ntchito: Chigawo chilichonse cha valve chili pansi pa hydraulic ndi mpweya kuyesa kuyang'anira ntchito molingana ndi pempho lokhazikika.

Valve Paint, phukusi ndi kutumiza.

Pempho la Special Quality Contor

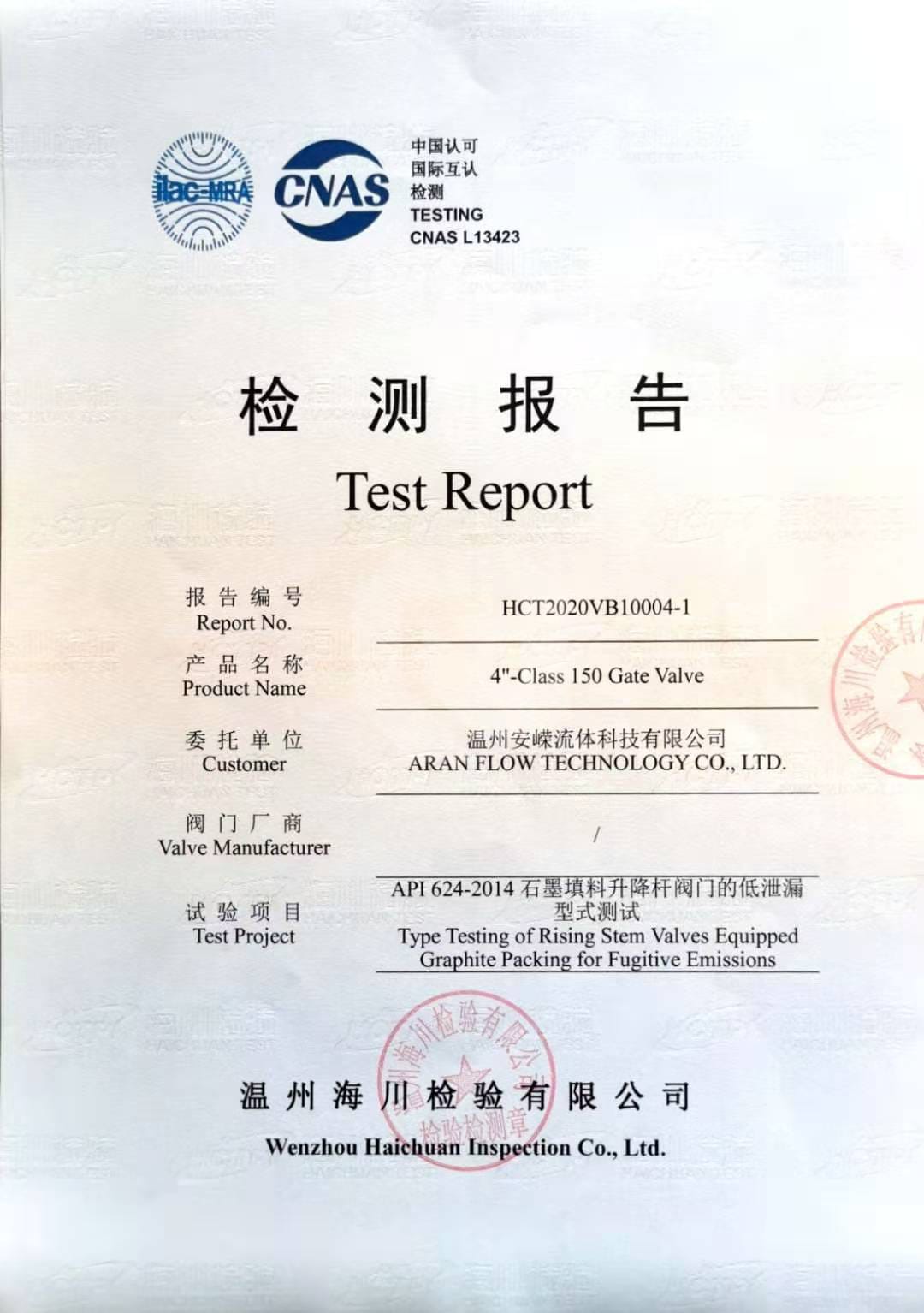

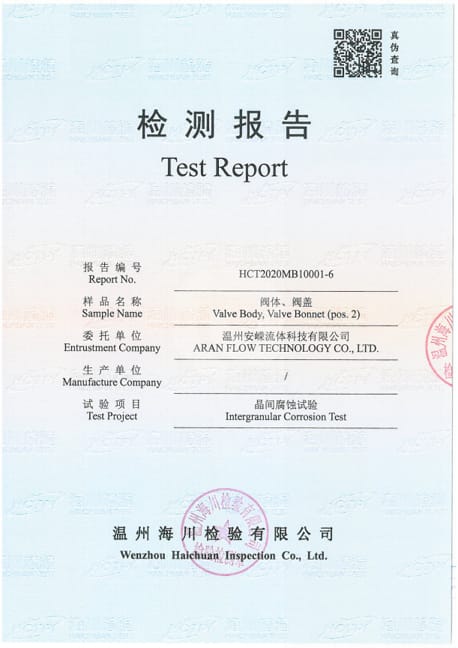

Lipoti la mayeso azinthu mu labu la anthu ena

- Kuyesa kwamakina ndi zotsatira

- Cheke wosanthula mankhwala

- Kuyesa kwa dzimbiri

- Kufufuza kwa Ferrite

- Mayeso a Hydrogen inducted cracking (HIC)

- Sulphide Stress corrosion testing test

Mayeso Osawononga (NDE, NDT)

Magwiridwe a VT, PMI, UT, PT atha kuchitidwa ndi m'nyumba ndi gulu lachitatu kuchita UT, PT, MT, RT ndi kuuma, ndikuphatikiza mulingo woyenerera wazinthu zomwe zonse zidzachitidwa acc.ku zofuna za makasitomala.

- VT (Mayeso Owoneka)

- PMI (Positive Material Identification)

- UT (Ultrasonic test)

- PT (Penetrant test)

- MT (Maginito tinthu mayeso)

- RT (mayeso a X-ray)

- Mayeso olimba

Pressure & magwiridwe antchito

Miyezo yoyesera ngati API 598, API 6D, ISO 5208, EN12266-1,GOST 9544 etc.

- Mayeso a Functional Test / Torque value test

- Mayeso a Hydraulic / Mayeso a Air

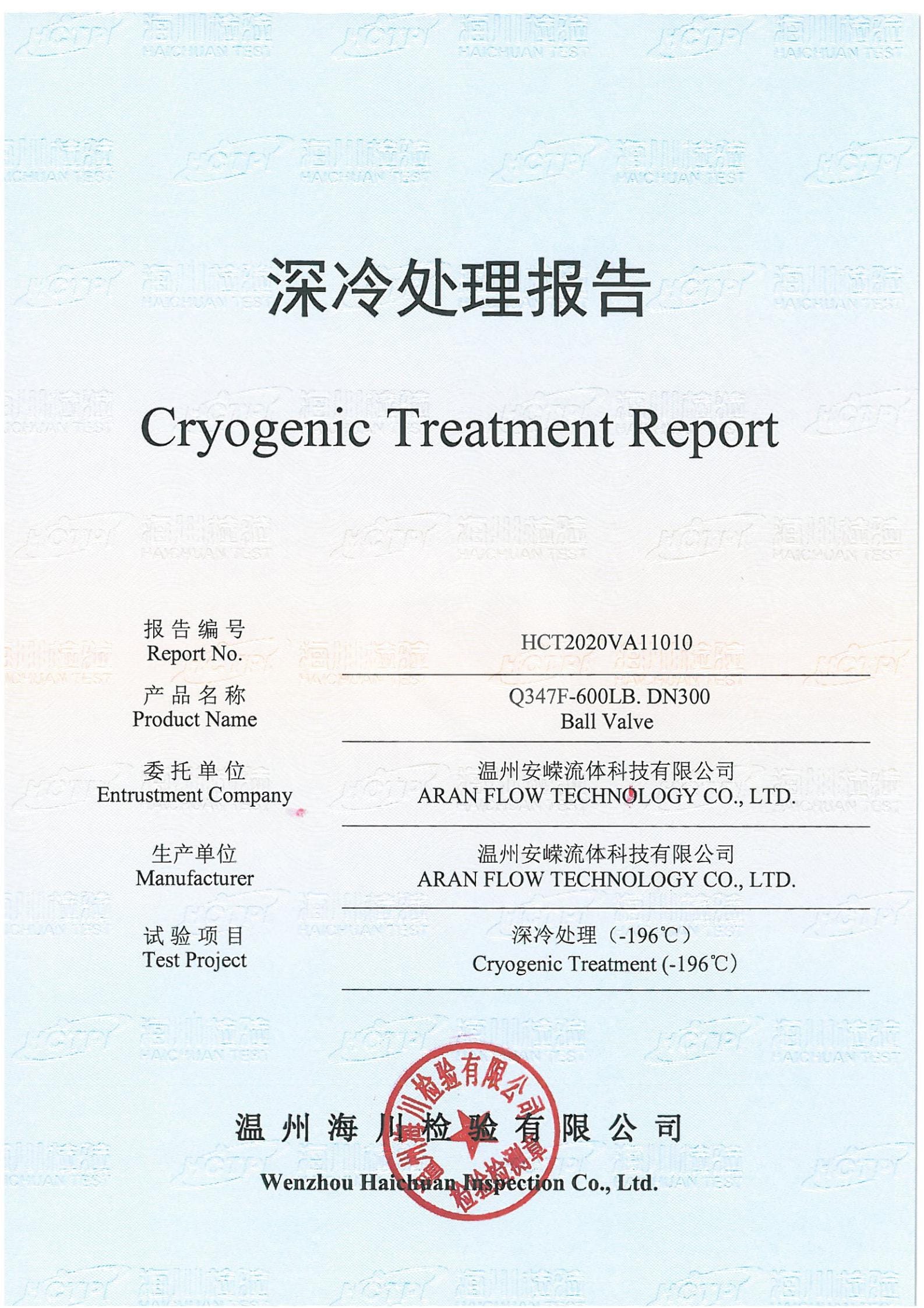

- Kutentha kochepa kwa mpweya wa Cryogenic Helium -196°C

- Kuyeza kutentha kwakukulu 600 ° C

- Mayeso a Fugitive Emission 15848-1 kapena 15848-2

- Kuyesa kotetezedwa ndi moto

- Mayeso a FAT (mayeso ovomerezeka a fakitale)

- Kuyesa kwa PAT (kuyesa kuvomereza kwazinthu)

Kuyeza kwa kutentha kochepa: malo otsika komanso otsika kwambiri a labotale kuti ayesere kutsika kapena kutentha kwambiri malinga ndi zofunikira.Mayesowa akuwonetsa valavu ku mayeso otsika kutentha Cryogenic mayeso -196 ℃ kapena kutentha kwakukulu -538 ℃